For reliability and total low cost of ownership, customers turn to ATRA-FLEX flexible couplings. We are proud to provide high-quality couplings that have been proven to increase efficiency and productivity for industrial applications worldwide since 1980.

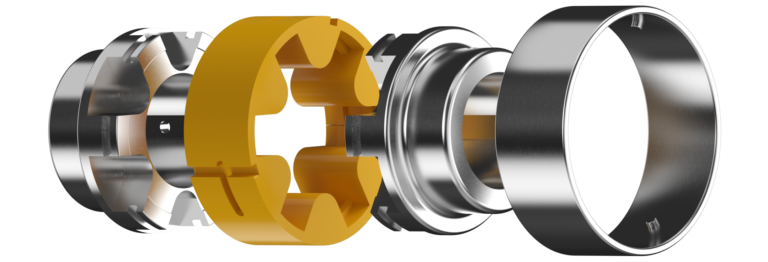

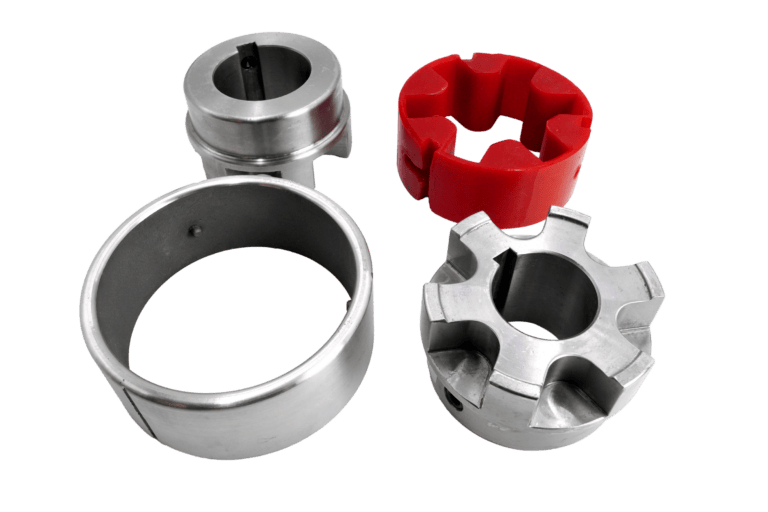

The M-Series close coupled couplings consist of four parts, two flex hubs, insert, and ring. The flex hubs are installed on the shafts with the ring twisted and locked over the flex hub. After coupling alignment, the insert is placed around the flex hubs engaging with the bottom lobes of the insert. The ring is then twisted and locked to engage with the insert. No fasteners or special tooling is required. M-Series uniquely combines the stability of a compression type coupling with the safety of a shear coupling. In the event of a lockup, the insert will shear, minimizing the possibility of damaging your rotational equipment. The rugged polyurethane insert is the only spare part and can be replaced in minutes without having to move the equipment or the shaft hubs.

M-Series USA-made standard hubs and rings are machined from solid carbon steel rounds and tubing, maintaining tight tolerances which provides excellent coupling balance. Stainless steels in grades 303,304 and 316 are also available for corrosive environments and food applications. We also offer a low-cost alternative to stainless steel that's called nitrocarburized. This gives our carbon steel a uniform case-hardened exterior layer and significantly preventing corrosion. Inserts are made from durable custom compounded polyurethane that offer resistance to almost every fluid found in industry today.

| Insert yellow | M-00 | M-0 | M-1 | M-1H | M-2 | M-3 | M-4 | M-5 | M-6 | M-7 | M-8 | M-9 | M-10 | M-12 | M-13 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CONTINUOUS (Nm) |

20,3 | 67,8 | 142,4 | 271,2 | 338,9 | 650,8 | 1423,5 | 3253,8 | 5423,0 | 12540,8 | 21082,1 | 30843,5 | 47451,6 | 108460,8 | 214662,0 |

| INTERMITTENT (Nm) |

33,9 | 113,0 | 237,3 | 451,9 | 564,9 | 1084,6 | 2372,6 | 5423,0 | 9038,4 | 20901,3 | 35136,8 | 51405,9 | 79086,0 | 180768,0 | 361536,0 |

| Insert red | M-00 | M-0 | M-1 | M-1H | M-2 | M-3 | M-4 | M-5 | M-6 | M-7 | M-8 | M-9 | M-10 | M-12 | M-13 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CONTINUOUS (Nm) |

17,3 | 57,6 | 121,0 | 230,5 | 288,1 | 553,2 | 1210,0 | 2765,8 | 4609,6 | 10659,7 | 17919,8 | 26217,0 | 40333,9 | 92191,7 | 182462,7 |

| INTERMITTENT (Nm) |

28,8 | 96,0 | 201,7 | 384,1 | 480,2 | 921,9 | 2016,7 | 4609,6 | 7682,6 | 17766,1 | 29866,3 | 43695,0 | 67223,1 | 153652,8 | 307305,6 |

| Insert orange | M-00 | M-0 | M-1 | M-1H | M-2 | M-3 | M-4 | M-5 | M-6 | M-7 | M-8 | M-9 | M-10 | M-12 | M-13 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CONTINUOUS (Nm) |

38,6 | 128,8 | 270,5 | 515,2 | 644,0 | 1236,5 | 2704,7 | 6182,3 | 10303,8 | 23827,5 | 40055,9 | 58602,7 | 90158,0 | 206075,5 | 407857,8 |

| INTERMITTENT (Nm) |

64,4 | 214,7 | 450,8 | 858,6 | 1073,3 | 2060,8 | 4507,9 | 10303,8 | 17173,0 | 39712,5 | 66759,9 | 97671,2 | 150263,4 | 343459,2 | 686918,4 |

| Insert green | M-00 | M-0 | M-1 | M-1H | M-2 | M-3 | M-4 | M-5 | M-6 | M-7 | M-8 | M-9 | M-10 | M-12 | M-13 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CONTINUOUS (Nm) |

9,9 | 33,1 | 69,4 | 132,2 | 165,3 | 317,2 | 694,0 | 1586,2 | 2643,7 | 6113,7 | 10243,7 | 15036,3 | 23132,7 | 52874,6 | 108743,3 |

| INTERMITTENT (Nm) |

16,5 | 55,1 | 115,7 | 220,3 | 275,4 | 528,7 | 1156,7 | 2643,7 | 4406,2 | 10189,4 | 17129,2 | 25060,4 | 38554,4 | 88124,4 | 176248,8 |